Application of tailored mould-injection techniques

Plastics technology

OUTSTANDING SOLUTIONS FOR SPECIAL REQUIREMENTS

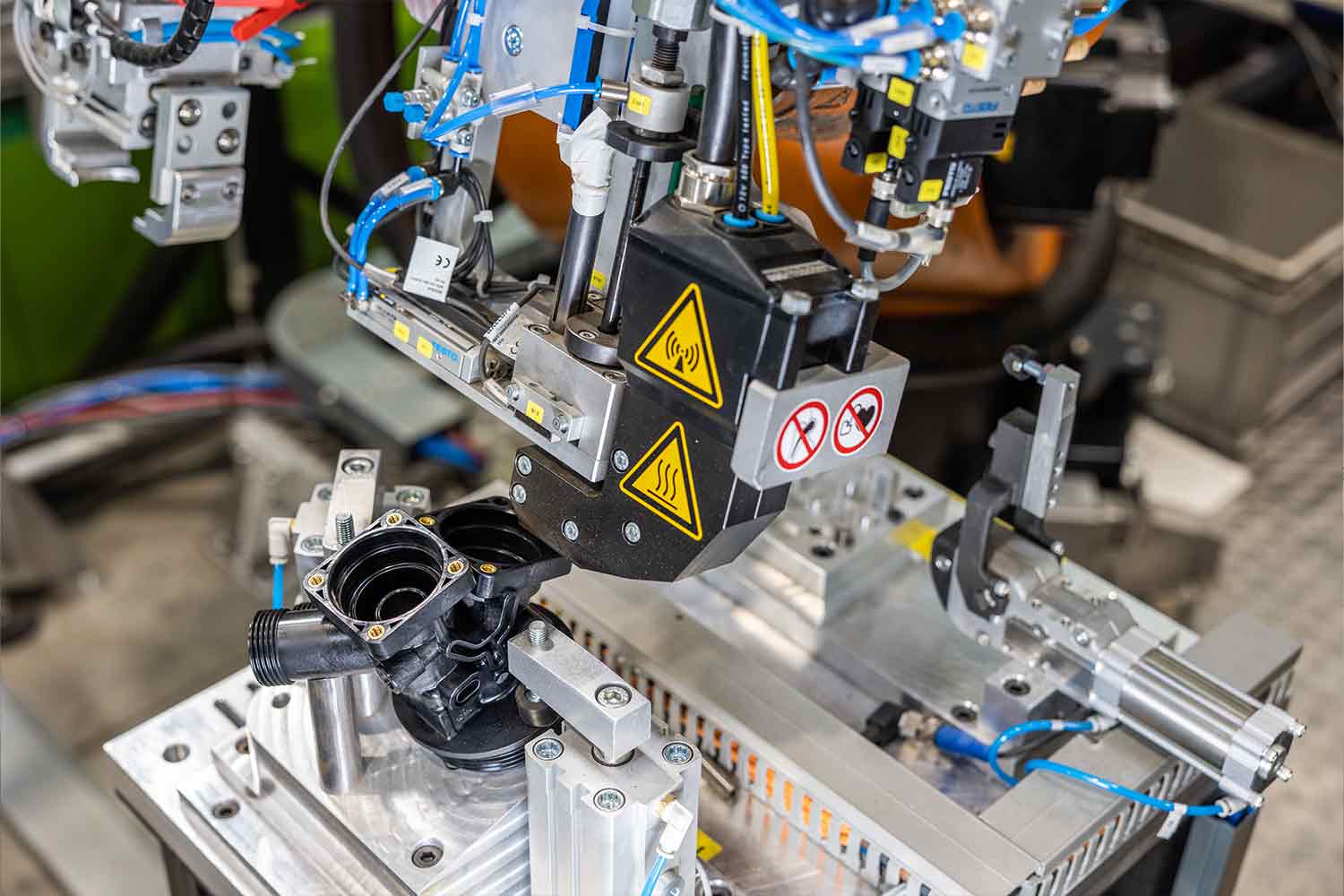

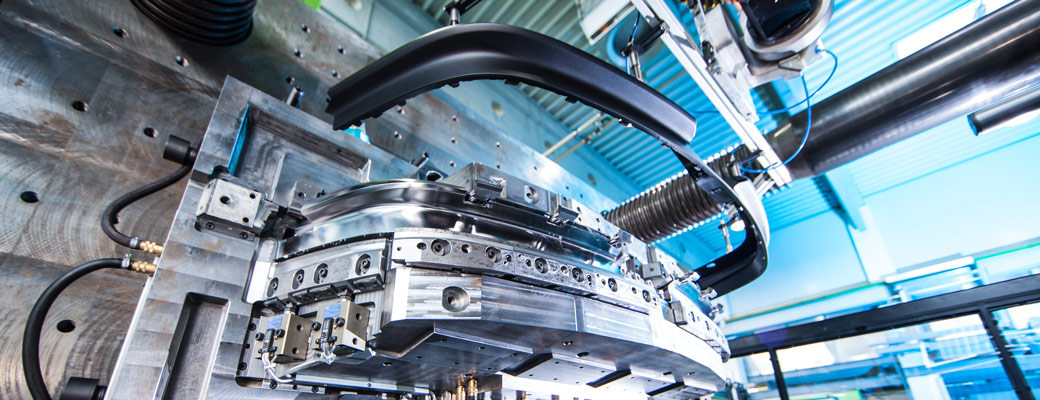

- Single- and multi-component technique with up to 4 components on fully automatic injection moulding machines

- Thermoplastic injection moulding and PUR processing techniques as well as their combination for a wide range of premium applications

- Foil back-injection technology for decorative and/or functional films

- Internal gas-pressure technology

- Organosheet technique and tape insert moulding

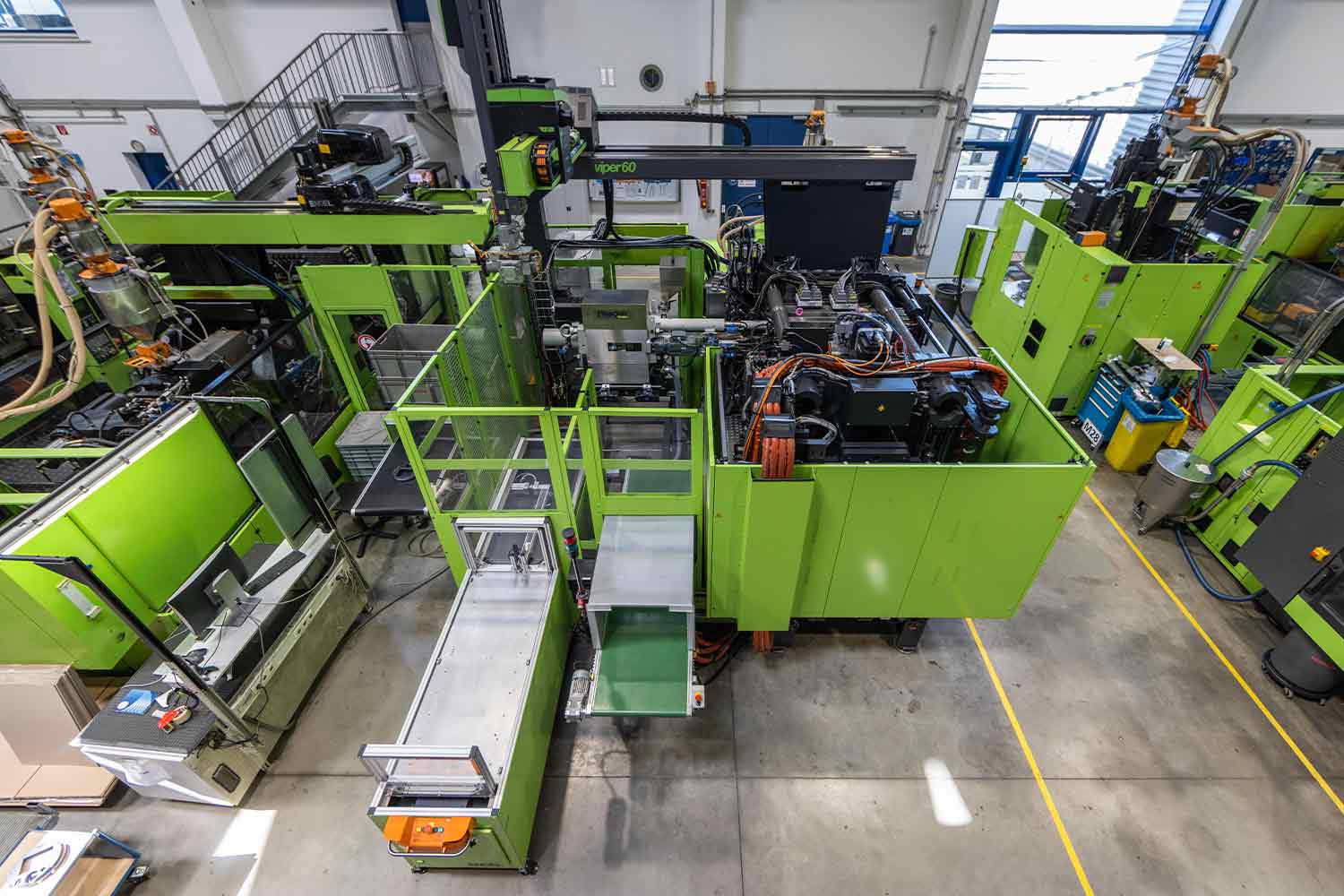

- Closing force range from 30 tons to 2,300 tons at the company site in Schwertberg, Austria

Solutions from Schöfer allow innovative partial development with advanced mould injection techniques for both the series production as well as the batch production of premium components. Visible parts with brilliant and highly attractive surfaces can be manufactured with Schöfer solutions as required for the automotive sector or other consumer-related applications. This allows demanding decorative elements with a high-quality surface for the automobile branch as well as for other branches with high visual requirements to be manufactured. Where light construction elements and components are required, we supply the suitable injection moulding process. We are well versed in the international manufacturing standards. Furthermore, we work closely together with our customers to develop customized solutions for unique demands. Our motto is “Creative Moulding Solutions!”