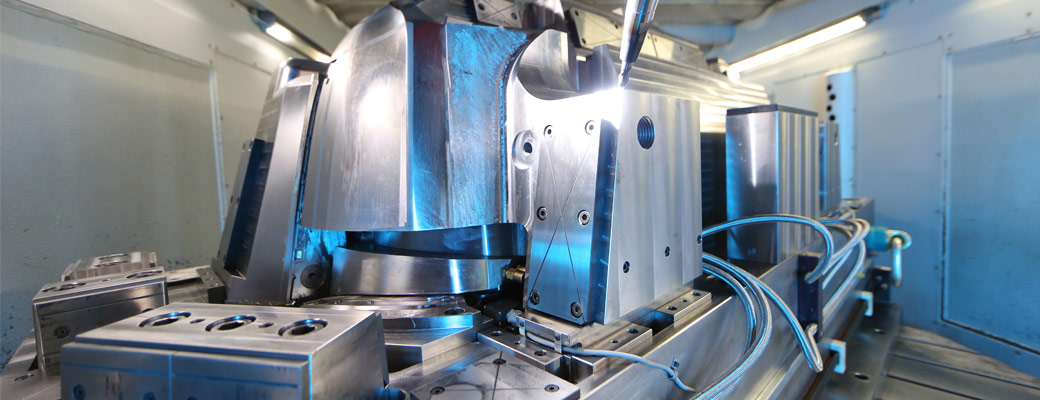

Injection moulds for construction components with demanding surfaces and/or with a focus on lightweight construction

Mould manufacture

TECHNOLOGY AND PRECISION WORKMANSHIP AT ITS BEST

- Thermoplastics injection moulding (single and multiple-component technology)

- Film back injection technology (IMD, IML, PMD, Varioform, functional films)

- PUR high-pressure processing

- PUR low-pressure processing

- Stamping technology

- Thermoplast reactive injection moulding (in-situ polymerization)

- Process combinations for multi-component construction elements

- Separate and integrated systems for the automation, measurement and control of mould injection processes as well as devices for reworking and assembly solutions

Schöfer excels in the design and manufacture of complex plastic moulds of all sizes. This is particularly true for the production of highly specialized tools that are used for attractive visible components, particularly in the automotive and electronics branches. This is a core competence of Schöfer. The company unites outstanding machinery with the engineering excellence of experienced and highly trained personnel to ensure high process quality and precision. Close contact with customers and business partners, permanent feedback about our performance as well as our focus on innovation allows us to continually optimize the tools and components that we produce. From the original idea for the mould construction up to series production, Schöfer is your partner of choice.