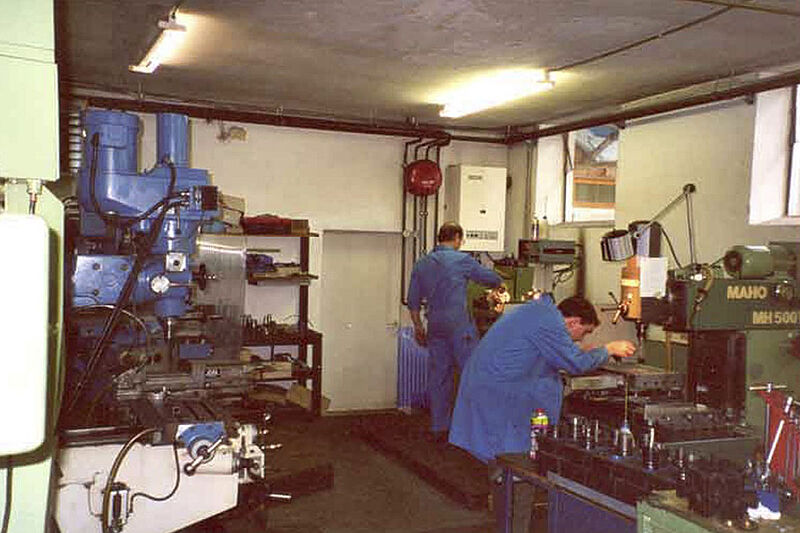

1990

Company founding by Helmut Schöfer as a mould shop

1991

Investment in first injection-moulding machine for mould trials and optimization, followed by the first orders for injection-moulding parts

1992

Entry into the automotive supply industry

1999

Nomination of Helmut Schöfer as a jury member of the Society of Plastics Engineers (SPE) in recognition of his innovative tooling solutions in the automotive industry

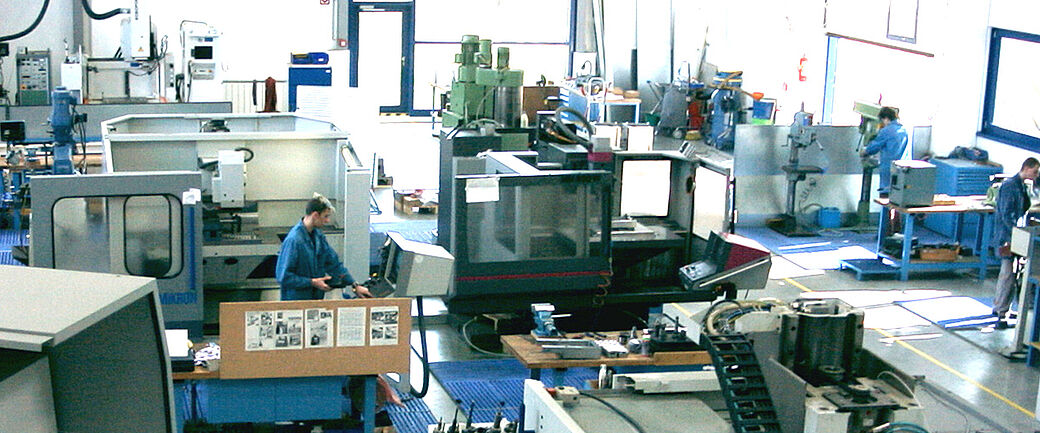

2001

New location site in Schwertberg, Furth 17, with a focus on sustainability as well as on a striking internal and external architectural appearance. The company site with 1.4 hectares (3.5 acres) allows the working environment to be dynamically customized to people and processes. Plant site start-up with 40 employees.

2003

Implementation of a quality management system in accordance with ISO 9001 certification

2004

Introduction of gas-injection technology and foil-injection moulding

2005

– Entry of Gerald Schöfer into the company management

– Major investments in buildings and machinery to extend the production capacity to 30 tons of mould weight and 2,300 tons of clamping force

2009

First presentation of mould solutions with PUR Clearmelt Technology

2010

Implementation of an environmental management system with certification according to ISO 14001

2012

Investment in 2K PUR Foaming Technology

2013

First presentation of mould solutions for in-situ polymerization of caprolactam

2015

Implementation of fully integrated ERP/PDA/MES solutions to improve processes and to fully connect customer and supplier systems

2016

– Investment in a HP-RTM plant for PUR Clearmelt processes

– Demonstration of an in-situ polymerization process during the K Fair at the Engel booth

2017

– Start of an innovation project in cooperation with Business Upper Austria for the technical optimization and new development of injection moulding processes

– New piston metering unit for our HP-RTM plant for processing colored PUR systems

2018

Participation of the Leonhard Kurz Foundation as a shareholder of Schöfer GmbH

2019

Demonstration of DecoPUR Technology (TP/PUR) developed by the Leonhard Kurz Group using an automotive front module as an example

2022

– Investment in an ENGEL duo 1300 combi M 3-K injection moulding plant with reversing-plate technology

– Demonstration of a 2K IMD-decorated rear-end automotive cover